Blog

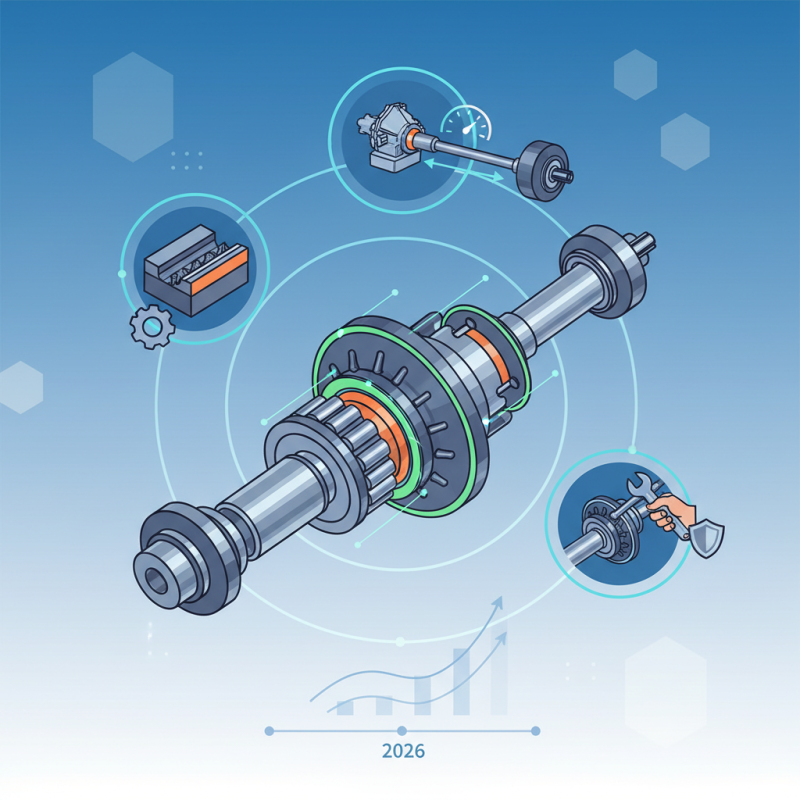

2026 Best Center Bearing Types for Optimal Performance?

In the world of automotive engineering, the significance of the Center Bearing cannot be overstated. Industry expert John Mitchell has said, “Choosing the right center bearing is crucial for vehicle performance.” This statement underlines the importance of making informed choices in selecting center bearings for optimal functionality.

Center bearings play a vital role in supporting the driveshaft, ensuring a smooth transfer of power from the engine to the wheels. However, not all center bearings are created equal. Variations in materials and designs can affect performance and longevity. Regular maintenance and proper installation are essential for maximizing efficiency. Each vehicle has unique requirements, and finding the right fit can be challenging.

As we approach 2026, the market for center bearings continues to evolve. New technologies emerge, but many choices can overwhelm consumers. The task remains: how do we select the best options? Identifying the flaws in existing products can lead to better improvements. Reflecting on the past can guide advancements for the future. Understanding the critical aspects of center bearings is key to enhancing overall vehicle performance.

Types of Center Bearings: An Overview of Options Available

When it comes to center bearings, several types cater to different needs. Understanding these options can drastically improve overall vehicle performance. A report by the Automotive Research Association highlights that the correct center bearing type can affect vehicle noise and durability by up to 20%.

One common type is the rubber center bearing, which provides flexibility and minimizes vibrations. Its softer material absorbs shocks well, but it may wear out quicker than other types. Metal center bearings offer higher durability but can transmit more noise. Recent data suggests that about 30% of drivers prefer rubber bearings for their quieter operation, even if they require replacement more frequently.

Composite center bearings are gaining traction. They combine aspects of both metal and rubber types. They offer a good balance between durability and noise reduction. However, some users note that they are often under-tested in extreme conditions. Finding the right center bearing involves weighing these factors carefully. Making the wrong choice can lead to unwanted noise and performance issues. The landscape of center bearings is complex and requires thoughtful consideration.

Key Factors Influencing Center Bearing Performance

When selecting a center bearing, several key factors come into play. The material used can greatly affect performance. Steel offers durability, while lightweight composites can enhance fuel efficiency. According to a recent industry report, bearings made from advanced materials can reduce friction by up to 15%, boosting overall vehicle efficiency.

Vibration dampening is another critical aspect. Excessive vibrations can lead to premature wear and tear. A study indicated that optimizing the design of the bearing housing can cut vibrations by nearly 30%. This improvement not only extends the life of the center bearing but also enhances passenger comfort.

Tips: Regular inspections can identify issues early. Consider the operating temperature range for best performance. Ensure proper installation to avoid future complications. A little hindsight can save a lot of time and money later. The choice of center bearing is crucial for optimal functioning, but it’s easy to overlook these details. Paying attention now can lead to significant benefits down the road.

Comparison of Center Bearing Materials and Durability

When selecting center bearings, material matters. Steel, plastic, and rubber are commonly used. Each material has its own strengths and weaknesses. Steel offers high durability and strength but can corrode. Plastic is lightweight and resistant to chemicals, but it may wear out faster. Rubber provides flexibility but can degrade over time.

Durability is a crucial factor. Steel bearings can withstand heavy loads but may fail in harsh environments. Plastic bearings, while resistant to some elements, may struggle under high stress. Rubber, often used in various applications, can tear or crack under intense pressure. Evaluating the performance in real-world conditions can lead to surprising outcomes.

Installation plays a big role in performance, too. Misalignment can cause premature wear. Regular maintenance is key to extending the lifespan, but not everyone prioritizes it. Balancing cost and quality can lead to tough decisions. Choices made today can have lasting impacts. Understanding your specific needs is essential in making the right choice.

Installation Guidelines for Optimal Center Bearing Functionality

When installing a center bearing, proper attention to detail is crucial. Start by ensuring you have a clean working environment to avoid dust and debris. The initial step involves supporting the drive shaft securely. This prevents any unexpected movements that could lead to misalignment. Misalignment can cause vibrations, reducing overall performance.

Next, check the mounting brackets and ensure they are in good condition. Worn-out brackets can result in instability during operation. It's advisable to replace any damaged components before proceeding. Proper torque specifications are essential when tightening the bolts. Over-tightening can lead to stress and damage, while under-tightening may result in inadequate support.

During installation, aligning the center bearing with the drive shaft is critical. This may require some adjustments. Ensure a straight path to avoid unnecessary wear over time. Lastly, consider reviewing your installation process. Reflection on any challenges faced can enhance your skills for future projects. Small errors can be costly, so learning from them is vital for optimal performance.

2026 Best Center Bearing Types for Optimal Performance

This chart illustrates the performance metrics of various types of center bearings based on their vibration levels and load capacities. The optimal center bearing types show lower vibration levels while maintaining high load capacity, ensuring better functionality.

Maintenance Tips for Prolonging Center Bearing Lifespan

Center bearings play a crucial role in vehicle performance. They support the drive shaft and help with stability. However, many overlook their upkeep. To prolong the lifespan of center bearings, regular maintenance is essential.

One key maintenance tip is to keep them lubricated. Proper lubrication reduces friction and wear. Ensure that you use the right type of lubricant. Also, check for any signs of damage or wear. Inspect for cracks or unusual noises during operation. If you notice anything strange, address it promptly. Ignoring these signs can lead to further issues.

Another effective practice is to keep them clean. Dirt and debris can cause significant damage over time. Regularly clean the area around the center bearing. Use a soft cloth and avoid harsh chemicals. Sometimes, it is tempting to skip cleaning due to time constraints. However, this can have negative consequences later. A little effort in maintenance now can save costs and headache later.

2026 Best Center Bearing Types for Optimal Performance

| Bearing Type | Material | Load Capacity (lbs) | Operating Temperature Range (°F) | Lifespan (Hours) |

|---|---|---|---|---|

| Standard Steel | Steel | 1500 | -40 to 200 | 5000 |

| High-Performance Composite | Composite | 1800 | -20 to 250 | 7000 |

| Heavy-Duty Metal | Metal Alloy | 2200 | -40 to 300 | 10000 |

| Rubber Dampened | Rubber & Steel | 1200 | -20 to 180 | 4000 |