Blog

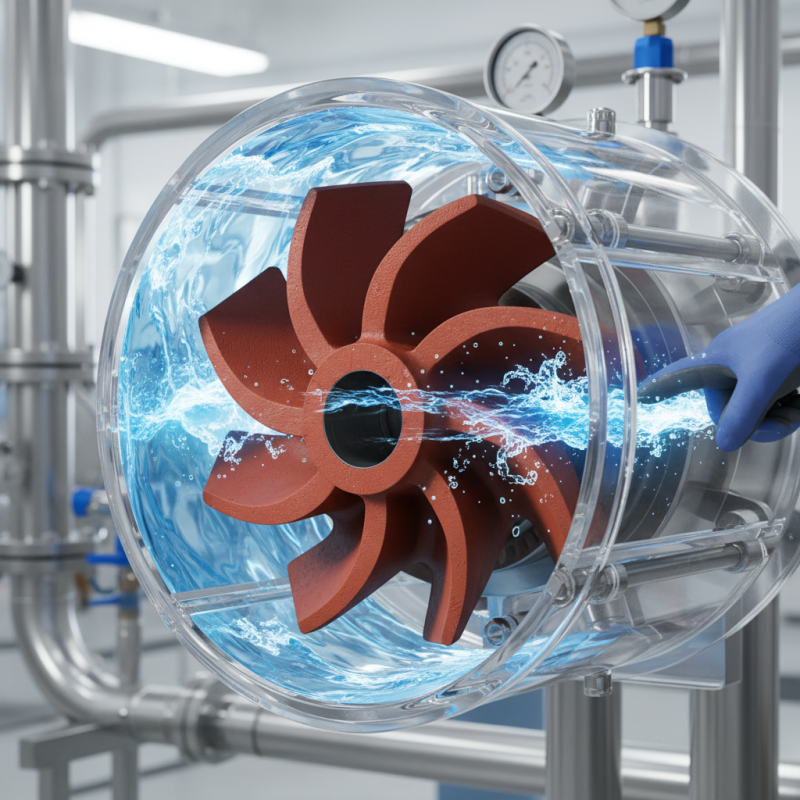

How to Choose the Right Rubber Pump Impeller for Your Needs?

Choosing the right Rubber Pump Impeller can significantly impact operational efficiency. Experts in the industry, like John Carter, emphasize the importance of selecting the proper impeller. He states, “The wrong choice can lead to performance issues and increased costs.”

Many factors influence the selection process. For instance, consider the specific application requirements, including flow rate and pressure. Each project differs, and a one-size-fits-all solution often fails. Assessing these needs is crucial to find a compatible Rubber Pump Impeller.

An incorrect decision may result in unexpected failures or inefficiencies. A deeper understanding can prevent wastage and improve performance. In the world of rubber pump technology, knowledge is power. Making informed choices shapes success in the long run.

Understanding the Functionality of Rubber Pump Impellers

Rubber pump impellers play a crucial role in the efficiency of fluid transfer systems. These components determine how well the pump performs under various conditions. According to industry reports, about 75% of pump failures relate to impeller issues. This illustrates why choosing the right impeller is vital for operational success.

Understanding the material properties of rubber is essential. Rubber impellers often provide excellent wear resistance and flexibility. This can result in a longer lifespan compared to metal alternatives. However, not all rubber grades are suitable for high-temperature scenarios. Some can lose their effectiveness under heat, leading to costly repairs. It's important to assess the specific application requirements carefully.

Moreover, impeller design impacts performance significantly. A wrong design choice can lead to cavitation or decreased flow rates. Industry data shows that optimizing impeller geometries can enhance efficiency by up to 20%. But, maintainability is often overlooked. Selecting an impeller that is easy to service can save money in the long run. These factors should continuously be examined to ensure you’re making the best choice for your specific needs.

How to Choose the Right Rubber Pump Impeller for Your Needs? - Understanding the Functionality of Rubber Pump Impellers

| Impeller Type | Material | Flow Rate (GPM) | Pressure (PSI) | Application |

|---|---|---|---|---|

| Closed Impeller | Nitrile Rubber | 50 | 40 | Industrial Water Transfer |

| Open Impeller | EPDM Rubber | 70 | 30 | Chemical Processing |

| Vortex Impeller | Natural Rubber | 40 | 25 | Sludge Removal |

| Semi-Open Impeller | Neoprene Rubber | 60 | 35 | Wastewater Management |

| Magnetic Drive Impeller | Hypalon | 80 | 50 | Pharmaceuticals |

Identifying Your Pump System Requirements for Impellers

Choosing the right rubber pump impeller begins with understanding your pump system's specific requirements. Each system has its unique demands, including flow rate, pressure, and the type of fluid being pumped. Consider the environment where the pump operates. Is it abrasive? Is it corrosive? These factors can greatly influence the longevity and efficiency of an impeller.

Next, evaluate the compatibility of materials. Rubber impellers can serve various applications, but not every type will work in any situation. The hardness of the rubber, its resistance to chemicals, and temperature tolerance are crucial. Even among rubber options, there's a spectrum of characteristics. It can be confusing. Take the time to research and match those specifics to your needs.

Another aspect worth considering is the potential for wear and tear. Monitor the pump's performance regularly. If you notice a drop in efficiency, you may need to reassess your choice. Ask yourself if the selected impeller meets all the operational requirements. Taking shortcuts in this process might lead to costly downtime later. Reflection on your choices extends beyond selection; it encompasses maintenance and replacement timings too.

Evaluating Material Options for Rubber Pump Impellers

Choosing the right material for rubber pump impellers is crucial. The material dictates performance, durability, and adaptability. Common options include natural rubber and synthetics. Each has unique properties that impact function.

Natural rubber offers excellent elasticity. It can handle flexing without cracking. However, it may not resist chemicals well. On the other hand, synthetic options like EPDM or Nitrile can withstand harsh environments. They provide better chemical resistance. But, they might lack flexibility compared to natural rubber.

Consider the specifics of your application. What fluids will the pump handle? What temperatures are involved? These factors are vital in making your choice. It’s easy to overlook these details. Testing different materials could reveal unexpected outcomes. This process may take time, but it’s often necessary to find the right fit for your needs.

Comparison of Rubber Pump Impeller Material Options

Assessing Size and Design Criteria for Optimal Performance

Choosing the right rubber pump impeller involves careful consideration of size and design. Size influences flow rates and efficiency. According to industry reports, a mismatch can lead to a 20% drop in efficiency. Smaller impellers may require higher RPMs, increasing wear and energy consumption. An improperly sized impeller can also lead to cavitation, causing damage and costly repairs.

Design is equally crucial. A well-designed impeller enhances fluid dynamics. The shape can impact performance significantly. For instance, a closed impeller is often more efficient than an open one. Reports indicate that closed designs can improve performance by up to 30%. However, not all applications require high performance. Sometimes, simplicity may yield more reliable uptime but at the cost of efficiency.

It's important to regularly assess operational needs. Specifications often change, and this can affect impeller choice. A good design today may not be sufficient tomorrow. Including adjustable features can help adapt to fluctuating needs. Keeping up with trends and data in the industry is vital for making informed decisions. Balancing design, size, and operational demands is not easy, but it’s necessary for optimal performance.

Recognizing Common Applications and Industry Standards for Selection

Choosing the right rubber pump impeller involves understanding common applications and industry standards. Impellers are crucial in various sectors, from agriculture to wastewater management. In agriculture, for instance, a study noted that rubber impellers enhance efficiency by 15%. This increase can significantly affect crop yields.

When selecting an impeller, consider its resistance to wear and chemical exposure. The American National Standards Institute (ANSI) recommends specific ratings to ensure durability. Typically, a hardness rating of 60-70 Shore A is ideal for general applications. However, some environments may require softer or harder materials. Always evaluate the operating conditions before making a choice.

Tip: Always assess the fluid you’ll be pumping. Some fluids can degrade rubber quickly, leading to increased maintenance costs.

In addition, temperature and pressure ratings play a vital role. The Hydraulic Institute suggests checking for compatibility with your specific application. Impellers often operate at various speeds, which can directly impact performance. A mismatched impeller can lead to inefficiencies and potential system failures.

Tip: Test your impeller in real conditions to understand its performance better. This trial can highlight potential shortcomings early on.