Blog

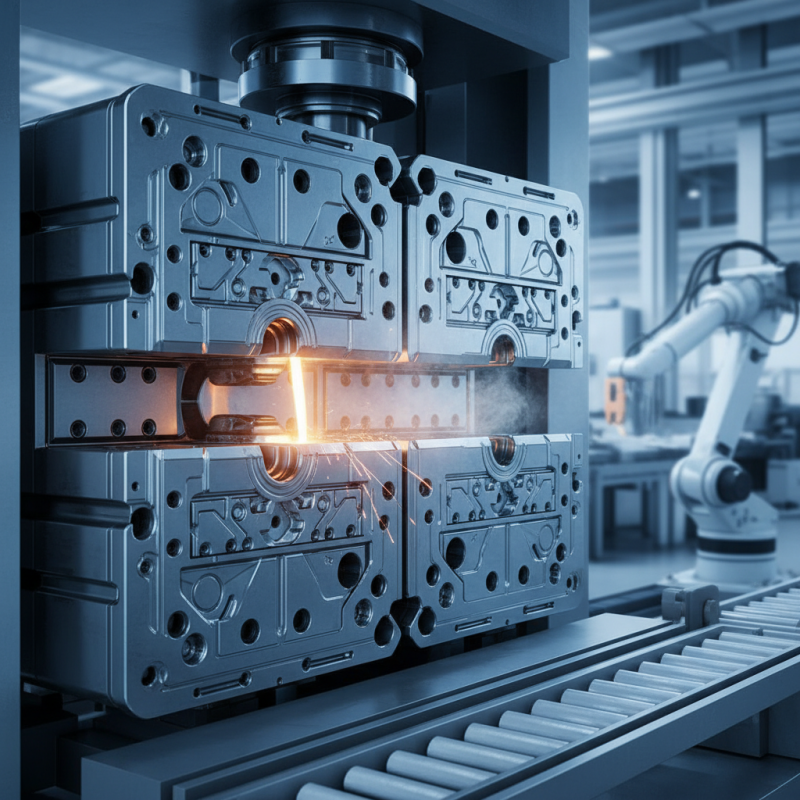

Why Are Die Casting Molds Important for Manufacturing Success?

Die Casting Molds play a crucial role in the manufacturing sector. These molds are essential for producing high-quality metal parts. According to the "2022 Global Die Casting Market Report," the industry is projected to grow at a CAGR of 5.4%. This highlights the increasing demand for efficient manufacturing solutions.

John Smith, a leading expert in die casting technology, emphasizes, “The precision of Die Casting Molds determines the overall success of the production process.” This statement underscores the importance of investing in advanced mold technology. Quality molds reduce production time and costs, leading to enhanced operational efficiency.

However, many manufacturers overlook the significance of Die Casting Molds. Some still use outdated molds, resulting in higher defect rates and longer cycle times. Businesses must prioritize mold design and maintenance to avoid setbacks. The mold's quality directly impacts customer satisfaction and market competitiveness. As the industry evolves, addressing these challenges is key to thriving in the competitive landscape.

Importance of Die Casting Molds in Manufacturing Processes

Die casting molds play a crucial role in manufacturing processes, significantly affecting quality and efficiency. They shape molten metal into precise designs. A well-crafted mold ensures consistency in dimensions, reducing waste. Inconsistent molds can lead to defects, which increase production costs. Each mold must be designed with care to avoid common pitfalls.

The longevity of a die casting mold is also essential. High-quality materials can withstand repeated use, but they can wear down over time. Regular maintenance is necessary to preserve their performance. A mold that fails unexpectedly can halt a production line, causing delays.

Moreover, the complexity of a mold's design can impact the production process. Some molds may require intricate features that are hard to produce. This complexity can lead to longer manufacturing times. Balancing design and practicality is essential for operational success. Keeping these aspects in mind can help manufacturers reflect on their current practices and improve their output.

Importance of Die Casting Molds in Manufacturing Processes

Key Features of Die Casting Molds That Enhance Product Quality

Die casting molds play a crucial role in manufacturing. They are designed for precision, which directly influences product quality. A well-crafted mold ensures consistent results. It minimizes defects in the final products. The choice of materials for these molds can significantly impact durability. High-quality steel or aluminum for molds often withstands the pressures of molten metal. This resilience contributes to longer production runs.

Another important feature is the cooling system within the mold. Efficient cooling helps maintain uniform temperatures. This reduces the chances of warping or other imperfections during production. However, achieving the right balance is challenging. Overcooling can lead to brittleness, and undercooling may cause defects. It's a delicate dance of temperatures.

Mold design also affects the surface finish of the products. A finely polished surface leads to better aesthetics and reduced post-processing needs. Nevertheless, some designs can be complicated, posing manufacturing challenges. Adjustments may be necessary to achieve desired outcomes. Each choice points to the importance of thoughtful design in the die casting process. It's about finding solutions and learning from imperfections along the way.

Why Are Die Casting Molds Important for Manufacturing Success? - Key Features of Die Casting Molds That Enhance Product Quality

| Feature | Description | Impact on Product Quality |

|---|---|---|

| Material Selection | Using high-quality steel or aluminum for durability and heat resistance. | Improves mold lifespan and reduces defects caused by wear. |

| Precision Engineering | Accurate machining of molds for precise dimensions and tolerances. | Ensures consistency in product dimensions and fit. |

| Cooling Systems | Incorporating effective cooling channels for uniform cooling. | Reduces cycle times and minimizes residual stress in cast parts. |

| Surface Treatment | Utilizing coatings or treatments to prevent adhesion and corrosion. | Improves mold life and reduces the likelihood of defects. |

| Design Flexibility | Ability to create complex shapes with integrated features. | Enhances product functionality and aesthetics. |

The Role of Material Selection in Die Casting Mold Performance

Material selection plays a critical role in die casting mold performance, directly affecting production quality. Typically, molds are made from high-alloy steel or aluminum. Each material has unique properties that can enhance performance or limit durability. For instance, high-alloy steels are often chosen for their toughness and heat resistance, making them suitable for high-pressure applications. Aluminum molds, while lighter, tend to wear out faster.

According to a recent industry report, nearly 30% of mold failures are attributed to improper material choice. This underscores the need for careful selection based on the components being produced. High-quality materials can result in significantly improved mold life, reducing overall costs. However, not all manufacturers prioritize this aspect, leading to repeated failures.

Environmental factors also take a toll on material performance. Humidity and temperature fluctuations can alter the mechanical properties of the chosen materials. Some manufacturers neglect this, resulting in defects that impact the final product. Better understanding and testing can mitigate these issues. Selecting the right material requires experience and strategy, highlighting the complexities of die casting mold formulation.

Cost Efficiency and Production Speed: The Benefits of Die Casting Molds

Die casting molds play a crucial role in the manufacturing sector. They enable high-speed production of complex parts. This process is efficient and costs effective, making it appealing for many businesses. High-quality molds can lead to better final products. Every detail matters in design, as flaws can affect the entire production line.

Cost efficiency stems from the ability to produce large volumes quickly. These molds can be reused multiple times, reducing the cost per unit significantly. Producing a part in a minute or less is possible. However, creating and maintaining molds requires investment. If not managed properly, costs can spiral unexpectedly. Regular maintenance is essential, as wear can lead to defects.

Production speed is another benefit. With faster cycle times, businesses can meet tight deadlines. Swift production allows for quick adjustments to designs. However, overemphasizing speed can lead to oversights. Quality checks are still necessary. Every cast needs scrutiny. Balancing speed and quality remains a critical challenge in the industry.

Challenges in Die Casting Mold Design and Maintenance Strategies

Die casting molds play a crucial role in the manufacturing process. However, designing and maintaining these molds comes with significant challenges. According to a recent industry report, nearly 30% of unsuccessful die casting projects stem from mold-related issues. Common problems include wear and tear, misalignment, and cooling inefficiencies. The complexity of mold design increases as product specifications become more intricate.

Maintenance strategies are essential in mitigating these issues. Regular inspections can identify wear patterns early. Implementing a proactive maintenance schedule reduces unexpected downtime. Data shows that companies investing in maintenance see a 20% increase in productivity. Mold cleaning, lubrication, and temperature control are key factors. Neglecting these can lead to defects and increased costs.

Tips: Monitor mold usage closely. Track performance metrics and usage time. Conduct routine checks to spot potential issues. Keep records of maintenance activities for better analysis. A well-maintained mold is less likely to fail. Investing in quality maintenance pays off in the long run.