Blog

Top Tips for Choosing a Lamination Machine for Your Needs?

Choosing the right Lamination Machine can be challenging. Experts suggest considering your specific needs carefully. John Smith, a renowned expert in the lamination industry, once stated, "Selecting the right machine can enhance your productivity significantly." His words emphasize the importance of matching a machine to your requirements.

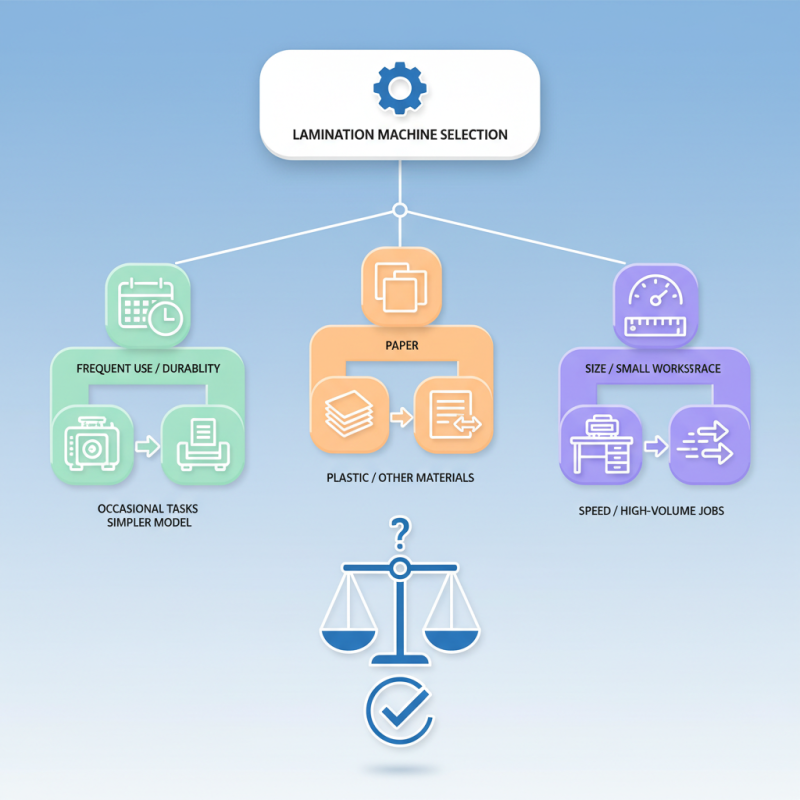

When exploring options, think about how often you will use the Lamination Machine. Frequent use demands durability and ease of operation. For occasional tasks, a simpler model might suffice. Also, consider the types of materials you'll laminate. Some machines excel with paper, while others handle plastic better. Understanding these details is crucial.

Many buyers overlook the importance of machine size and speed. A compact machine might fit perfectly in a small workspace but may lack in speed for high-volume jobs. Reflection on such choices can be revealing. Finding balance between size, speed, and functionality is not always straightforward. Always ask yourself, will this machine truly meet my needs? Making an informed choice here is vital for long-term satisfaction.

Understanding the Different Types of Lamination Machines Available

Choosing the right lamination machine can greatly enhance your productivity. There are various types of lamination machines available, each designed for specific needs. They typically fall into three main categories: pouch laminators, roll laminators, and thermal laminators. Pouch laminators are ideal for home or small office use. They are compact and user-friendly.

Roll laminators are better suited for larger projects. They can handle larger materials and offer more speed. Thermal laminators use heat to seal the laminate. These are often favored in professional settings due to their durability. However, the type you choose should align with your project requirements.

When selecting a lamination machine, consider the volume of work you expect. If it's low-volume, a pouch laminator may suffice. If you anticipate high demand, a roll laminator could be more efficient. Remember, the quality of the finished product is essential. Invest in a machine that offers consistent results.

One key tip is to look for user reviews and expert recommendations. It's also wise to compare warranty options. These can save you money on repairs in the long run. Take your time to find the best fit for your needs. It can be a significant investment, so doing your research pays off.

Key Features to Look for in a Lamination Machine

When selecting a lamination machine, consider key features carefully. One important aspect is the type of laminating process. Some machines use thermal technology while others rely on cold lamination. Thermal laminators are popular for their efficiency but may not work well with heat-sensitive materials. Cold laminators, on the other hand, are versatile and safer for fragile items.

Additionally, check the machine's sheet capacity and speed. Some machines handle multiple sheets at once, making them suitable for larger jobs. A slow machine might frustrate users who need quick results. Look for adjustable temperature settings. This feature allows users to customize settings based on the material being laminated.

Portability is another factor. If you plan to move the machine frequently, lightweight models are easier to transport. However, lighter machines might lack durability. Assess your workspace too, as larger machines require more room. Finally, consider the price. Cheaper models may lack essential features, while high-end models may offer unnecessary extras. Finding the right balance is vital and requires reflection on your specific needs.

Assessing Your Volume and Frequency Needs for Lamination

When choosing a lamination machine, understanding your volume and frequency needs is crucial. Do you plan to laminate frequently or just occasionally? Assessing your requirements can save you money and time. For small offices or home use, a compact machine may suffice. If demand spikes, consider a machine with greater capacity.

Think about the types of materials you will be laminating. Will they be standard sheets, or do you need different sizes? Heavy-duty machines are better for larger projects. However, they come with a higher price tag. Choose one that fits your needs, not just for now but also for future projects.

Tip: Always check the machine's warm-up time. Some may take too long, which can slow down your workflow. Consider models that are user-friendly, especially if multiple people will operate the machine. A confusing interface can lead to mistakes and wasted resources. Ultimately, reflect on how often you laminate. Are you overestimating your needs? Choose wisely based on actual usage rather than assumptions.

Budget Considerations When Choosing a Lamination Machine

When choosing a lamination machine, budget is paramount. The market offers a wide range of prices. Entry-level machines can cost around $100, while high-end models may exceed $1,000. According to recent industry reports, the average small business spends approximately $500 on a quality machine. Understanding your budget helps refine your options.

Consider your laminating needs. If you’re primarily laminating documents, a simple model suffices. However, for larger formats or thicker materials, invest more. Some reports indicate that businesses overlook long-term costs like replacement sheets or repairs. Initial savings could result in ongoing expenses later.

It's crucial to think about the machine's durability and maintenance costs. Low-cost machines often compromise on longevity. A thorough analysis of user reviews highlights that cheaper models frequently malfunction. This can lead to increased downtime and frustration. Your budget should reflect both initial purchase and future requirements.

Maintenance Tips for Prolonging the Life of Your Lamination Machine

When it comes to maintaining your lamination machine, regular care is crucial. Start by keeping the machine clean. Dust and debris can easily accumulate. This buildup may affect performance. A simple cloth can work wonders when cleaning surfaces. Don’t forget to check the rollers too. Any sticky residue can lead to uneven lamination.

Next, inspect the heating elements regularly. Over time, these components may wear down. If you notice any irregular heating, adjust the temperature settings. If problems persist, it might be worth consulting a technician. Lubrication is also essential. Refer to the user manual for specific instructions. Skipping this step may shorten the machine’s lifespan.

Another aspect is storage. Proper storage can prevent unnecessary damage. If possible, keep it in a dry, safe place. Avoid areas with high humidity. Remember, even small adjustments in your routine can lead to better longevity. It’s about being attentive to details. Sometimes, it's easy to overlook the obvious.