Blog

Understanding the Functionality of the Overflow Valve Block?

The functionality of the Overflow Valve Block is crucial in hydraulic systems. John Smith, an expert in fluid mechanics, once stated, “Understanding each component is key to optimizing system performance.” This highlights the significance of knowing how the Overflow Valve Block operates.

Overflow valves ensure that hydraulic systems operate within safe pressure limits. A properly functioning Overflow Valve Block prevents catastrophic failures. However, many engineers overlook its importance. Not understanding this component can lead to inefficiencies.

Consider a scenario where the Overflow Valve Block is improperly calibrated. This issue may result in system pressure surging. Such problems often go unnoticed until it is too late. A thorough understanding of the Overflow Valve Block can prevent these costly mistakes. By reflecting on these challenges, one can appreciate the intricate role this valve plays.

Overview of the Overflow Valve Block in Hydraulic Systems

The overflow valve block plays a pivotal role in hydraulic systems. It ensures pressure regulation and system safety. A properly functioning overflow valve can prevent equipment damage and leaks. Industry data indicates that improper pressure management can lead to failures, costing companies up to 15% of their operational budget. This highlights the importance of a reliable overflow valve block.

Hydraulic systems rely heavily on these components. When the pressure exceeds safe limits, the overflow valve activates. This prevents excessive pressure from causing catastrophic failure. According to recent studies, over 25% of hydraulic system failures are due to pressure-related issues. Regular maintenance of the overflow valve block is crucial. Neglected valves can lead to inefficiencies and increased wear on system components.

Monitoring the flow and pressure is essential. Data suggests that 40% of hydraulic systems operate at suboptimal pressure levels, which can degrade performance. Operators should regularly check their overflow valves. This is an often-overlooked aspect of system maintenance, yet it can significantly impact overall efficiency. Awareness of these details is vital for optimal system operation.

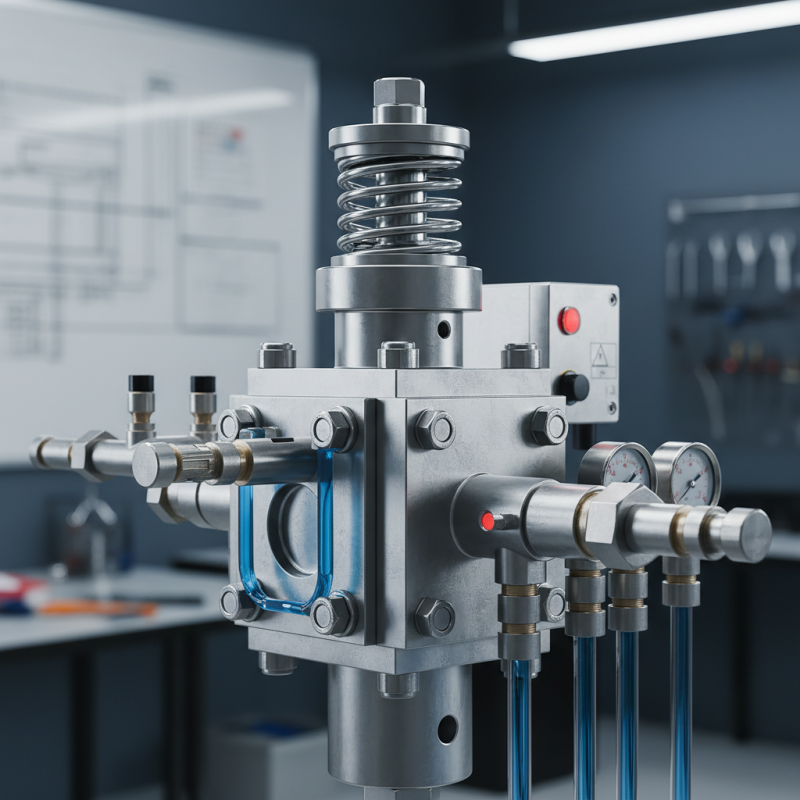

Key Components and Mechanism of the Overflow Valve Block

The overflow valve block plays a vital role in hydraulic systems. It prevents fluid pressure from exceeding safe levels. When pressure rises, the overflow valve opens. This allows excess fluid to divert, protecting equipment from damage. Understanding how it functions is crucial for maintenance.

Key components of the overflow valve block include the valve, spring, and housing. The valve regulates the flow of hydraulic fluid. The spring controls the opening pressure. These parts work together seamlessly to ensure safety. Any malfunction can lead to serious issues. Leaks or stuck valves degrade system performance.

Inspection of the overflow valve block is necessary. Regular checks can catch wear or damage early. However, many overlook this. They assume the component will always function flawlessly. This can be a costly mistake. Ensuring each element works properly enhances the overall efficiency of the hydraulic system. It is worth taking the time to monitor it closely.

Functionality and Role in Pressure Regulation

The overflow valve block plays a crucial role in pressure regulation systems. This component ensures that the pressure within a system does not exceed safe limits. Without it, over-pressurization can cause equipment failure or hazardous situations. According to a report by the International Society for Automation, pressure regulation failures account for nearly 30% of industrial accidents.

The functionality of the overflow valve block begins when pressure levels rise unexpectedly. The valve opens, allowing excess fluid to escape. This process stabilizes the system. However, not all overflow valves perform optimally. Some may fail to reset after activation, leading to inefficiencies. Regular maintenance checks are vital to ensure reliability.

Tips: Always monitor pressure levels closely. Utilize sensors to alert you to potential issues. Don't ignore minor leaks; they can signal underlying problems. Addressing these small issues can prevent larger failures down the line. Understanding your system's specific requirements is essential for effective pressure management.

Understanding the Functionality of the Overflow Valve Block? - Functionality and Role in Pressure Regulation

| Dimension | Value |

|---|---|

| Pressure Setting Range | 5 - 150 psi |

| Response Time | < 0.1 seconds |

| Material | Aluminum Alloy |

| Operating Temperature | -20°C to 80°C |

| Flow Capacity | 100 L/min |

| Port Size | 1/2 inch NPT |

| Safety Features | Pressure Relief, Anti-Scalping |

Common Applications of the Overflow Valve Block

The overflow valve block plays a crucial role in hydraulic systems. It helps manage excess pressure effectively. This is essential for ensuring safety and maintaining equipment integrity. In many industrial settings, the overflow valve block is a go-to solution for controlling hydraulic fluids.

Common applications of the overflow valve block can be found in construction machinery. These machines often operate under high pressure. The overflow valve block prevents dangerous pressure buildups, which could lead to system failures. It's also used in agricultural equipment, where precision is vital. In such scenarios, maintaining optimal pressure ensures that operations run smoothly.

In the realm of automotive systems, these valves can help regulate hydraulic brakes. They ensure that the braking system operates effectively, providing safety. However, misuse of the overflow valve block can lead to significant issues. Sometimes users may overlook proper maintenance, leading to malfunctions. This could result in unwanted consequences. Awareness and education about the overflow valve block are necessary for all users.

Maintenance and Troubleshooting Tips for Optimal Performance

The overflow valve block plays a crucial role in maintaining system pressure. A well-functioning valve ensures that excess pressure is released safely. Any malfunction can lead to serious issues. Regular maintenance is key to optimal performance.

Check the valve regularly. Look for leaks or unusual noises. Keep the surrounding area clean. Debris can hinder the valve's function. If you notice erratic pressure fluctuations, it could signal a problem. Inspect the valve seat for wear and tear. Consider replacing seals if they appear damaged.

Be proactive in troubleshooting. Understand the symptoms of a malfunctioning valve. Listen for hissing or vibrations. These may indicate internal issues. If the valve fails to open or close properly, you may face pressure build-up. Regularly test the valve response to ensure efficiency. This ongoing attention can prevent costly repairs later.